and Protection

Laxmi Power Solutions is well known name when it comes to Chemical Earthing Products and Equipment whether its Chemical Earthing, Earthing Electrodes, Chemical Back Fill Compound, Copper Bonded Earthing Rods or Conventional Earthing.

The most important thing for understanding in lightning protection is that not only a direct lightning strike act as a potential threat to the structure but also more frequently, electronic equipment is damaged by surges caused by remote lightning discharges (caused because of Lightning Electromagnetic Impulses LEMPs) or switching operations in larger electrical systems. During thunderstorms too, high volume of energy is instantaneously released. These voltage peaks can penetrate a building through Power, Data and Telephone cables causing heavy damage to Electronic Equipment.

The international standard for Lightning Protection referred as IEC 62305 – Protection against Lightning’, (which is also accepted by many countries as national standard) especially adopted by Bureau of Indian standard as IS IEC 62305, in one of its part explains the need of planning, erection, testing and maintenance of lightning protection systems for building structures without any height limit. The same is also implemented in new National Building Code – 2016, Part -8, Section 2 which also clearly defines the need of the measures to be taken care for planning, erection, testing and maintenance of lightning protection system. The standard IEC 62305 in its second part – Risk Management categorizes the four sources of Lightning as 1. Flashes to a structure, 2. Flashes near to a structure 3. Flashes to a service line, 4. Flashes near to a service line.

A proper lightning protection system design is very important to ensure increased protection of a building against Lightning and its effects. Systems followed in most of the buildings now are unfortunately not meeting the basic or statutory requirements. Since only a mere vertical air terminal will not solve the purpose for protection of building unless the entire building is sufficiently protected either with

1. Angle of protection method

2. Mesh conductor method or calculated as per rolling sphere method.

It is important to remember any best lightning protection implemented in the structure will not protect the personal outside the building (within the premises where the building is located). Since the angle of protection offered by the lightning protection terminal will only protect against direct strike, however induced step and touch potential will not be protected and which will lead to electrocution and causalities thereafter.

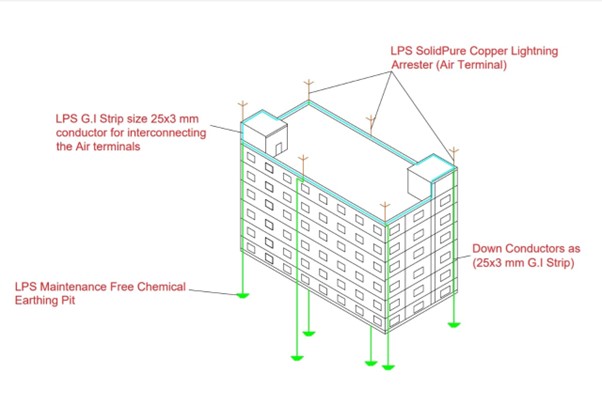

We have to join hands with the external lightning protection system and also with the down conductor leaders who can quickly forward it into the ground and ensure the lightning does not strike anywhere else in the structure, Basically A Proper Lightning Protection system should consist of the three prime components – Lightning Arrester made from material Copper or Aluminium along with Vertical and Horizontal Mesh, Down Conductors and Earthing System and it should also offers a least resistance path for the discharge of the Lightning Current. This measure should not be mis-understood that by providing external lightning protection our entire equipment / devices will get protected from damage. Separate measures as recommended in IEC 62305-4 Protection against Lighting: Electrical and Electronic system within the structure need to be followed and a proper and respective Surge Protection Device (SPDs) need to be employed individually for power line, data line and coaxial line for various applications such as electronic appliances, internet modems, television etc. Assume a television has failed due to lightning, the protection measure for that Television should be co-ordinated by employing SPDs at both power and Data inputs (satellite cable - coaxial cable terminated) since both sources are vulnerable of carrying lightning current. If this method is practiced, then damages can be avoided for such systems even if connection remains plugged. In both external lightning protection system and internal lightning protection system (SPDs) Earthing is an inevitable component, without which in both the cases dissipation of current is possible. Hence properly selected and properly maintained earthing is also needed for maximum safety in consolidation.

So whenever we apply a lightning protection, our engineers start the work by properly designing and measuring it so that there is no damage to the building during lightning. And as there are some buildings around which there are tall trees or high metallic towers, we also have to use ring earthing on such a places and All the Electrical Devices & Equipments should be protect with the help of Surge Protection Device (SPD’s) since the fatality due to lighting could be more disastrous for an equipment than a structural damage. Moreover, the installed protective devices tend to lose their visibility in due course due to various reasons. Periodic maintenance, monitoring and certification should be made mandatory for the effective functioning of the protective devices installed. For protection of Electrical, wiring, Electrical and electronic equipment, installation of Surge Protection Devices should be adopted.

Lightning Protection is often a challenge for the building designer when it comes to aesthetics of the building. Routing of down conductors through outer wall generally spoil the aesthetics of the building, due to which the down conductors are often routed through shafts, un-accessible areas, non-visible places etc. These down conductor increases the chance of fire and explosion in case of lightning. As a statutory requirement Lightning Protection is implemented in most of the buildings, but unfortunately in an inefficient way. Lightning flashes to, or nearby, structures (or lines connected to the structures) are hazardous to people, to the structures themselves, their contents and installations need to be considered for protection measures.

Therefore, we Laxmi Power Solutions (LPS) basically designed and work for Lightning Protection System first by taking all these point in to consideration:

• Type of Protection Clients Needs

• Level of Protection based on risk assessments.

• Technically qualified, certified products and equipment as per the latest appropriate standard.

• Sizes and dimensions of products, Components & Equipment’s.

• Locations of Air Terminal & Coverage Area.

• Conductor Routing and Connections.

• A Good Earthing System.

• Proper utilizations of all the components used in the particular project.

The Following guidelines are need to be follow properly for getting a safe and Good and optimum Lightning Protection System.

• A down conductor should be installed at each corner of Building and structure where this possible.

• The down Conductor should be in proper continuation from air terminal i.e. Lightning Arrester to Earthing Pit with minimum No’s of joint and connections as possible.

• Straight, Vertical so that they provide shortest and the most direct path to earth.

• The formation of loops between the down conductor should be avoided but where this is not possible the distance should be proper maintained.

• Connection of down conductors to gutters or down-spouts even if they are covered by insulating materials.

• Usage of multiple connection with different materials should not be permitted.

• Insufficient conductor dimensions (non-complying material as mentioned in IEC 62305-3 Table – 5) should be strictly avoided.

• When the distance from down conductors to combustible materials cannot be assured, the cross section of the down conductor shall not be less than 100 mm².

Secondly proper installation is very important in any Lightning Protection System which is best provided by our company Laxmi Power Solutions (LPS) in all over the India. Because We maintains & Give learning to our Engineers, Site Persons & Team.

Laxmi Power Solutions is well known name when it comes to Chemical Earthing Products and Equipment whether its Chemical Earthing, Earthing Electrodes, Chemical Back Fill Compound, Copper Bonded Earthing Rods or Conventional Earthing.

Graph of Industry growth depends upon Power Supply which is a

major hurdle which can bring down the company from its heights. It is actually a

necessity for most households and business entities.

Laxmi Power Solutions is well known name when it comes to Chemical Earthing Products and Equipment whether its Chemical Earthing, Earthing Electrodes, Chemical Back Fill Compound, Copper Bonded Earthing Rods or Conventional Earthing.

***We Promise, no spam!